Automatic Rotary OPP Hot Glue Labeling Machine

SVL-1508S-R

Stable Capacity: 15000-18000BPH

Technical Specifications

- This technical specification applies to the rotary OPP labeling machine and the technical requirements involved in functional design, structure, performance, manufacturing, installation, and trial production.

- The requirements, standards, and contents mentioned in this code are in compliance with national standards, power industry standards, and relevant international standards.

Mechanical Part

Host Machine (key device)

Mechanical Part

Conveying mechanism: adopts the power of filling or the conveying line of its own chain

304 stainless steel chain plate (can be designed according to customer specifications), chain width 82.6mm

The spindle support mechanism: adopts 2 single-acting cylinders and columns to form a triangular stable state.

Spindle lifting mechanism: adopt German SEW motor to control lifting, stable and accurate positioning.

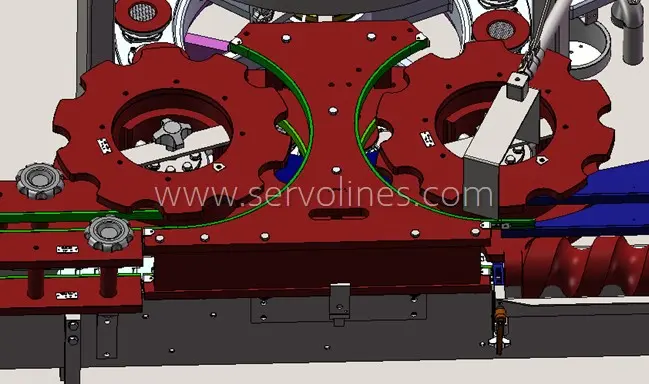

The gear transmission system of the whole machine.

Bottle rotation synchronous wheel transmission system.

Cam guide bottle pressing system.

Indenter drive system.

Front and back adjustment system for small machines.

Standard delivery mechanism:

High-speed servo OPP label film delivery system.

Glue supply system:

Special hot melt glue supply system (Japanese control system) to ensure the accuracy and uniformity of glue application.

Label turntable:

Two independent label disks are used to reduce the time used to replace label rolls in production and improve production efficiency.

High transmission power, compact structure of the transmission system, thin belt body, rich flexibility, suitable for high-speed transmission, low heat generation, stable rotation, heat resistance, oil resistance, wear resistance, low elongation in use, and long service life.

Bottle feeding mechanism:

Dedicated bottle feeding screw with torque limiter installed to ensure stable and reliable high-speed bottle feeding. Both the screw and bottle protecting push plate are fast.

The structure is dismantled, and all positioning and adjustment are completed at one time, no adjustment is required in the later period, and the replacement of the mold is simple and quick.

Bottle inlet and outlet star wheel:

Connected with the main turntable gear, responsible for the transition between the bottle feeding screw and the main turntable, install torque limiter, quick-release structure, and all have positioning, one adjustment is completed, no adjustment is required in the later period, and the replacement of the mold is simple and quick.

The Working Principle of Labeling

- The hot melt adhesive OPP labeling machine is a new type of labeling machine with the rotary and continuous operation; the equipment can automatically adjust the in and out the transmission of the container; the container conveyed by the conveyor belt is separated by the separation screw according to the spacing of the star wheel After a certain distance, the bottle-in star wheel transfers the container to the container turntable. After the container is fixed by the bottle pressing mechanism and the container’s mold seat, the container starts to rotate at a certain speed for positioning and labeling.

- When the container reaches the detection position of the electric eye, the computer host controls the label delivery system to deliver the label. When a label delivery action is completed, the high-speed cutter cuts off a label; due to the use of Yaskawa’s small inertia high-speed servo motor, high-speed label delivery is guaranteed. Accuracy and stability of label cutting.

- The cut labels are sent to the gluing system; in this part, the system applies glue to the two parts of the label’s leading and trailing edges. This gluing method minimizes the consumption of hot melt adhesive.

- When the glued label is transferred to the labeling position, the label can accurately and effectively adhere to the container. Since the container is in a rotating state during the transfer process of the label, the label can be affixed to the container smoothly and tightly. The adhesive strip at the end of the sizing can form a good label lap seal, completing the labeling process.

Equipment Safety Protection Function Part

Power monitoring:

When the power supply has overvoltage, Undervoltage, phase loss, or phase error, it will cut off the main circuit and give an alarm to prevent damage to electrical components.

Safety protection:

When the protective door is opened, the equipment is prohibited from running and starting, and the emergency stop switch can be pressed in an emergency state to prevent personal injury.

Label status: When the label is used up, it will slow down and stand by and give an alarm to remind you to replace the label. When the label tension is abnormal, it will stop and alarm to reduce the influence of label stretching on label cutting accuracy. When the color mark detection is continuously lost and the mark cut deviation is too large, the machine will stop and alarm to reduce the unqualified products.

Glue detection:

when the temperature of the glue does not reach the melting value, the equipment is prohibited from starting to prevent damage to the equipment. When the temperature of the glue exceeds the upper limit, the probe is open, and the heater is disconnected, it stops heating and shuts down and alarms. When the glue tank level is low, the glue When it is about to run out, it will give an alarm and wait for a delay in slowing down.

Missing labeling alarm:

When there is labeling missing, the equipment will slow down and stop the alarm to prevent the label drum from being cut and reduce the downtime.

Material control:

When there is a shortage of bottles at the end of the bottle or the end of the bottle is blocked, the equipment will slow down and stand by, the standby indicator will prompt, and the production speed will automatically resume after the state is released.

Device monitoring:

When the servo drive and variable frequency drive fail, and the control power supply is short-circuited, the equipment stops and alarms.

Air pressure detection:

When the air pressure does not meet the production requirements of the equipment, the equipment will be shut down to prevent the production of defective products.

Material clogging:

When the main turntable, the feeding screw, and the bottle star wheel are blocked and jammed, the machine will stop and alarm.

Equipment Technical Parameters

Model: | SVL-1508S-R |

Power supply: | 380VAC 3P+N+PE 50 Hz 10kW |

Labeling machine equipment length: | 3350mm (labeling machine conveyor belt length: 3000mm; can be adjusted according to the actual size of the customer's production line) |

Labeling machine host size: | 3000mm (length) X 2600mm (width) X 2400mm (height) |

Conveyor belt surface height: | 1050±50mm (can be adjusted according to the actual size of the customer's production line) |

Conveyor line speed: | 40m/min (conveyor line speed can be adjusted according to actual production conditions) |

Speed adjustment method: | stepless speed regulation |

Maximum labeling speed: | label maximum speed 100m/min |

Maximum labeling speed: | 18000BPH (adjustable according to production conditions) |

Labeling accuracy: | ±1mm |

The size of the object to be affixed: | according to the bottle sample provided by the customer (labeling after filling) |

Maximum label width (height): | 145mm (standard width, can be designed according to the actual product size) |

Maximum label length: | 300mm |

Maximum label outer diameter: | ø600mm |

Paper core diameter: | 152mm |

Labeling glue: | hot melt glue, only apply glue on both ends of the label |

Glue temperature: | 120~160℃ |

Label type: | OPP film label, paper-plastic composite film label |

Labeling station: | 15 stations per week for round bottle hot melt adhesive labeling machine |

Number of labeling molds: | According to the bottle specifications provided |

Labeling product type: | round bottle |

Whole machine weight: | about 3500kg |

Equipment Configuration

Name | Brand | Origin |

Ultra-high-speed motion controller | Japan | |

Machine interface | Taiwan | |

Central processing unit | Japan | |

Server driver | Japan | |

Servo motor | Japan | |

Frequency converter | Denmark | |

Intermediate relay | Japan | |

Contactor | USA | |

Breaker | Germany | |

Correction system | Germany | |

Power monitoring protection relay | Switzerland | |

Safety relay + safety switch | Germany | |

Intelligent power protector | Germany | |

Switching power supply | Taiwan | |

Emergency stop switch | France |

Reviews

There are no reviews yet.