Six Cavities Fully Servo High-Speed Blow Molding Machine

SVB-6C70

Stable Capacity: 9000~10000BPH Weight:≤20g

For 750ml~1500ml bottle, the Max. diameter can be 107mm, the Max. height can be 320mm

This 6-cavity machine can change to 3-cavity for 750ml~1500ml bottle, Capacity is 3300~3000 BPH/set

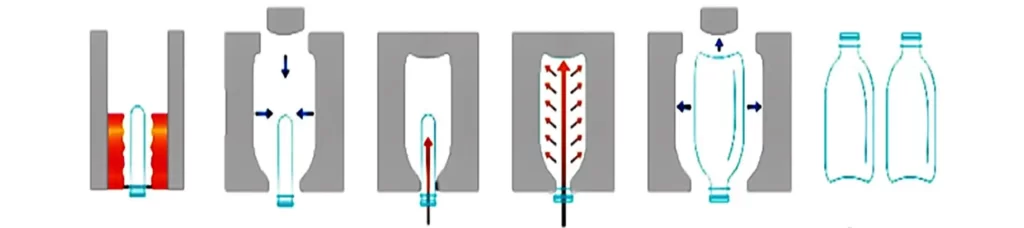

1. Technical Process:

2. Performance and Characteristics:

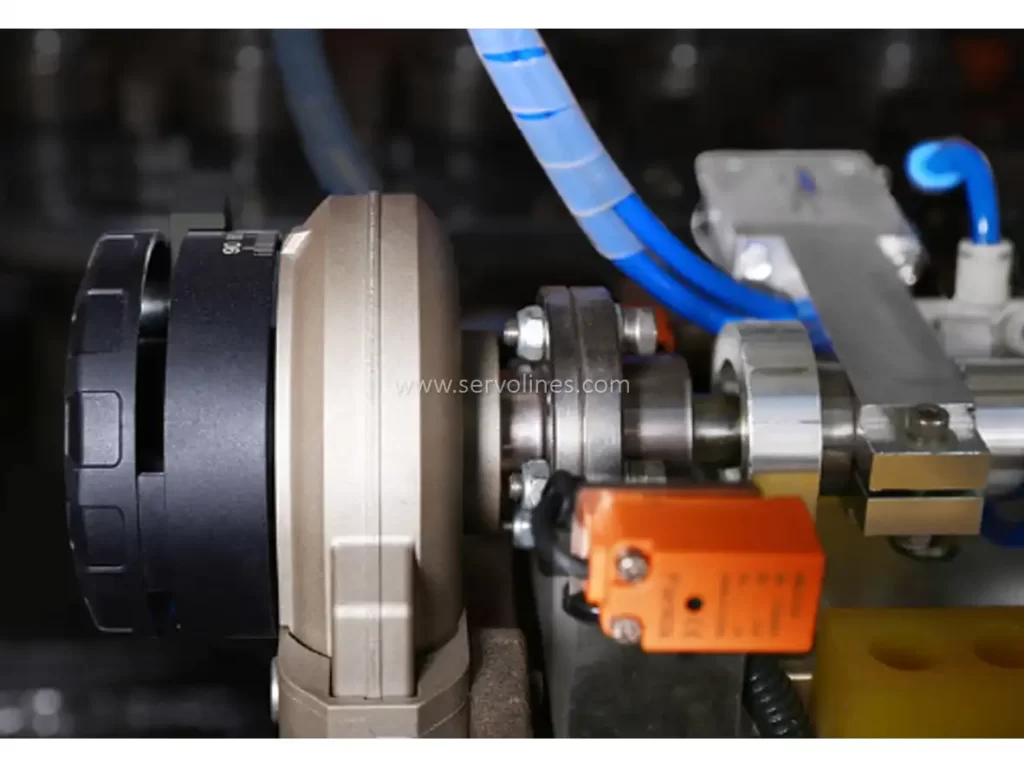

- The servo motor is adopted to drive the molding mechanism, triggering off a bottom mold linkage as well. The whole mechanism works speedy, accurately, stably, and flexibly.

Meanwhile, it is energy efficient and environmental safety. - The servo motor-driven stepping system and stretching system have improved the speed, flexibility, and accuracy of blowing.

Ÿ The high-pressure blowing system is also equipped with a gas recycling device (air recycling rate can be up to 30%)which may reduce power consumption by as much as 30kw per hour. That means you do not need the low-pressure air compressor anymore, which will minimize your investment as well as space for placing the machine. In one word, it is energy-efficient and environmental safety. - The simple slide-in way of mold mounting makes it possible for the operators to change molds easily within 30 minutes.

- The man-machine interface is highly automated and easy to operate. The compact machine occupies a smaller area.

- This series is widely used for making PET bottles for drinking water, carbonated soft drinks, medium-temperature filling drinks, milk, edible oil, food, pharmacy, daily chemical……etc.

3. Main Electric Component List

Name | Brand | Origin |

PLC | Japan | |

Revolving Cyliner for manipulator | Germany | |

Elevating Cylinder for manipulator | Germany | |

Cylinder for bottle handling | Germany | |

Servo Motor | Japan | |

Speed Reducer | Germany | |

Cylinder for preform feeding | Germany | |

Bottom Die Cylinder | Germany | |

Preform Pressing Cylinder | Germany | |

Motion Valve | USA | |

High Pressure Blowing Valve | USA | |

Intermediate Relay | Japan | |

AC Contactor, Thermal Relay | France | |

Intelligent Voltage Regulator | Japan | |

Silicon Control | Germany | |

Convertible Governor | Japan | |

Draught Fan for the heater | Taiwan | |

Mold-clamping lead rail | Taiwan |

4. Machine Main Parameter

Model: | SVB-6C70 |

Molding Spec. | |

Clamping force | 48000 kg |

Clamping stroke | 125 mm |

Stretching stroke | 240 mm |

Bottom stroke | 30 mm |

Cavity pitch | 76 mm |

Number of cavities | 6 cavities |

Container Spec. | |

Max.volume, ctr. | 750ml |

Neck diameter | Φ18~Φ38 mm |

Max.diameter, ctr. | Φ70 mm |

Max.height, ctr. | 240 mm |

THEORETICAL OUTPUT | 9000~10000 bph |

Power Spec. | |

Total power | 88 kw |

Power Consumption | 42 kw |

Heating Power | 39 kw |

Air Compressor Spec. | |

Blowing pressure | 35 Kg/c㎡ |

High pressure air consumption | 8 m3/min |

Water Chilling Spec. | |

Operating pressure | ≥4 Kg/c㎡ |

Temperature range | 5~20 ℃ |

Refrigerating capacity | 12222 kcal/hr |

Flow Rate | 5.16 m3/h |

Water Cooling Spec. | |

Operating pressure | ≥4 Kg/c㎡ |

Temperature range | ≤30 ℃ |

Flow Rate | 6.2 m3/h |

Main Machine Spec. | |

Size (L*W*H) | 4200*2050*2500 mm |

Weight | 5500 kg |

4. Machine Description

Automatic linear blow molding machines are applicable in a wide range of PET packaging practices, such as for water, beverages, edible oil, food, pharmaceutical products, cosmetics, etc. With more than 10 years of experience in developing and producing blow molding machines as well as the advanced technology absorbed domestic and abroad, we have developed with our constant innovation dozens of high speed and high precision equipment which have won the top reputation in the field.

Applicable range:

It is applicable for different pet water bottles and beverage bottles .oil bottles. normal filling bottles. hot filling bottles. CSD filling bottles.

Advantage:

- 1Touch screen Interface control, easy to operate

- Automatic preform loading and unscrambling

- servo driver control machine. speed higher, more stable. easy to adjust machine.

- Close structure, low contamination

- Well preforms-heating system

- The stable rotating system,

- Preforms are evenly heated, and easy to blow

- Low energy consumption, heating capacity is adjustable

- 9)machine uses a high air compressor. does not need a lower compressor. save cost and power. reduce to space.

Reviews

There are no reviews yet.